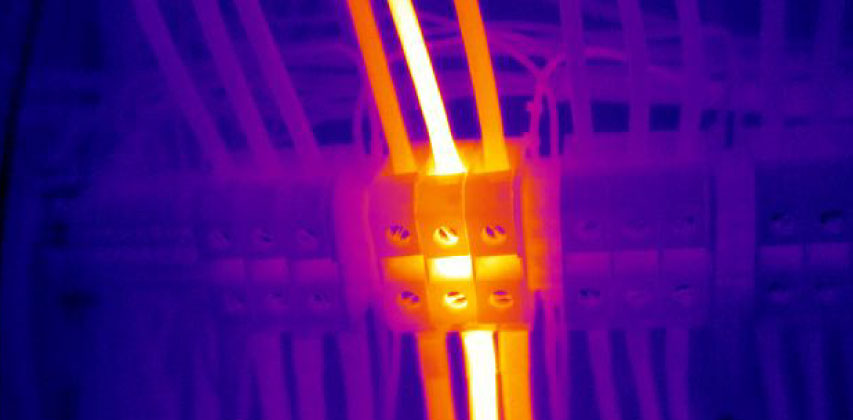

Prevent costly faults with non-invasive technology.

Often called thermographic surveys, this type of testing will detect electrical faults before the components fail. Using industry-leading cameras and software, Elecspec produce high-precision reports that identify any current problems, allowing you to take immediate action.

Why choose a thermographic survey?

- Avoid potential personnel risks, damage or fire hazards by quickly identifying heat sources or ‘hot spots’.

- Non-invasive and non-destructive tool that allows the survey to be completed while equipment and plant are still running.

- Depending on your organisation’s plant and equipment, thermal imaging surveys can reduce breakdowns, maintenance costs and any association production losses.

- Increases the lifespan of equipment.

What equipment should be tested?

Elecspec recommend that regular thermographic surveys are carried out on the following types of equipment:

- Fuse boards

- Control panels

- High and medium voltage systems

- Switchgear

- Power line connections and insulators

- UPS and battery systems

- PLC connections

- Motor control centres

- Busbar systems

This service can be added to any fixed wire testing carried out by the Elecspec team.

Working with Elecspec for your thermal imaging survey

The Elecspec team are fully trained to use all thermographic equipment, which delivers a detailed interpretation of images, and a detailed analysis into the root cause, and preventative repairs for the future.